PRODUCTS

AST: The Next Level of Turnkey

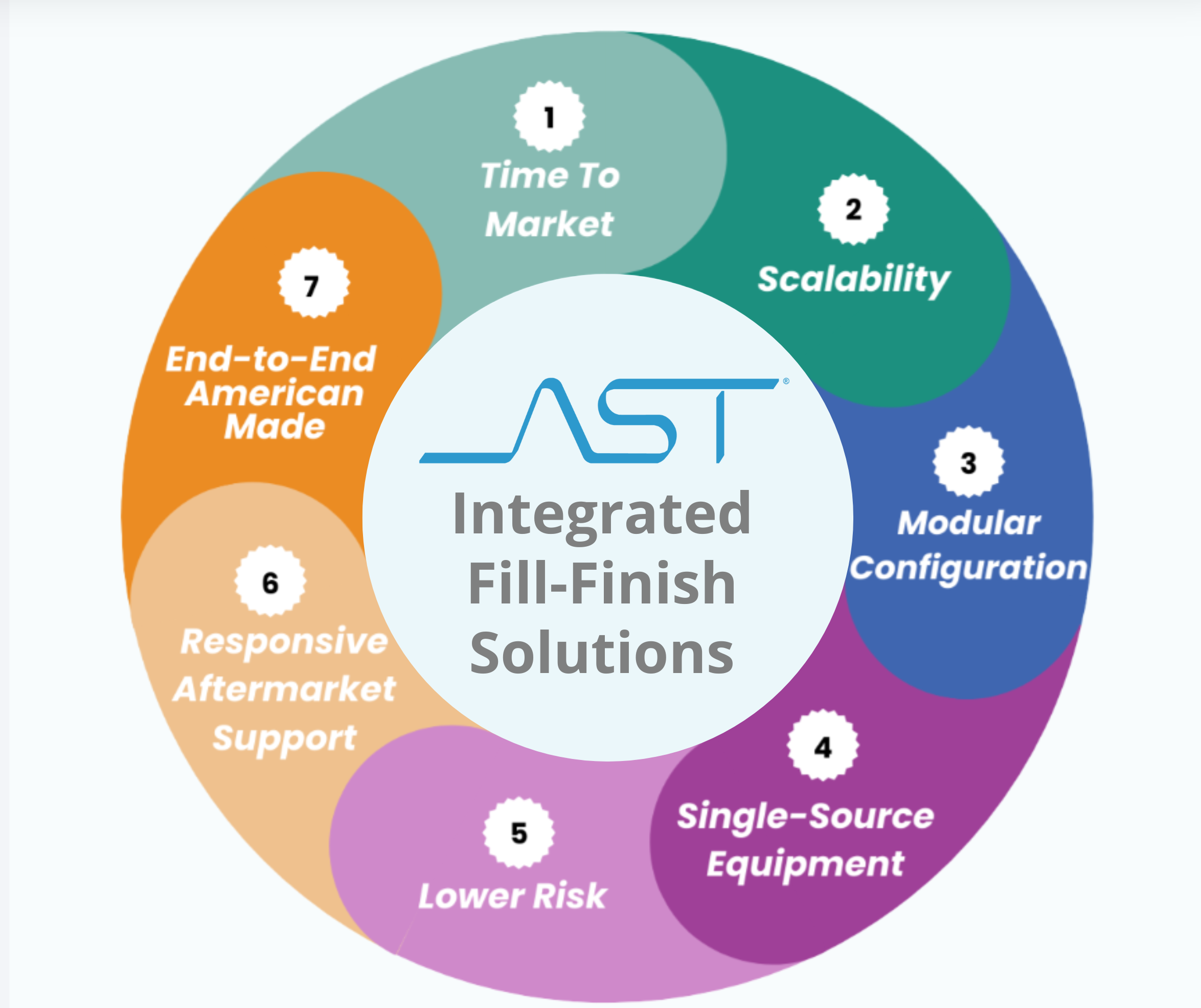

The current and future wave of pharmaceutical and biotechnology products is calling for higher standards of flexibility and innovation. AST’s advanced solutions have been designed to meet the production requirements of targeted medicines that dominate today’s drug manufacturing pipelines. Featuring a new level of integration, AST offers end-to-end, precisely engineered, single-source aseptic processing solutions. Our American-made turnkey solutions are supported by a localized model of supply and service that will maximize production uptime while offering your operation a new dimension of agility, durability, and responsiveness.

In the Know

Solutions for Every Stage of Product Development. Under One Roof. 100% Service.

- Unified FAT - Streamlined testing and commissioning executed to GMP standards and leveraged for quicker operational startup

- End-to-end native technology for seamless scaling and minimal revalidation requirements

- Improved lead and service response times

- Full operational lifecycle support, including preventative maintenance, cycle development, and aftermarket care.

- A Single centralized program control for decontamination, isolator, and fill line technologies

- Less risk and less time; Like-technology and streamlined processes cut down uncertainty, eliminate common cross-system obstacles, and ultimately result in better time-to-market for your drug products.

Liquid pharmaceuticals are rapidly evolving and being developed faster than ever, with a focus on modernized processes and rigorous compliance standards. Your aseptic processing solutions should rise to the occasion. AST’s integrated lines offer flexible, proven cGMP technologies. Dial in the start of your project and maximize production over the life of your operation with AST’s turnkey systems.

ASEPTiCell®

An adaptive system designed for commercial and clinical drug products, capable of filling and closing ready-to-use vials, syringes, and cartridges on a single integrated platform. The ASEPTiCell uses standard modules that can be easily configured to quickly tailor a system that meets each application’s unique requirements without the cost of customization.

GENiSYS®R

An adaptive aseptic filling and closing equipment designed to address the unique processing challenges posed by highly targeted applications such as cell, gene, and regenerative therapies. The GENiSYS R has a unique blend of automated capabilities that maximize product yield and ensure each container is processed in strict accordance with cGMP requirements.

Isolated GENiSYS C

An ultimate “multi-tool” for filling and closing vials, syringes, and cartridges with advanced automated features found on our larger-scale filling machines. The Isolated GENiSYS C features a highly compact footprint and advanced system features that make this system an ideal solution for small-scale filling applications like R&D, compounding pharmacies, process development, niche products, and targeted clinical and commercial manufacturing.