AST’s Director of Engineering Spencer Bolte walks through some of the key design considerations on AST’s new isolator including operator-centered solutions and a groundbreaking new decontamination technology for complete 60-minute cycle times, including aeration.

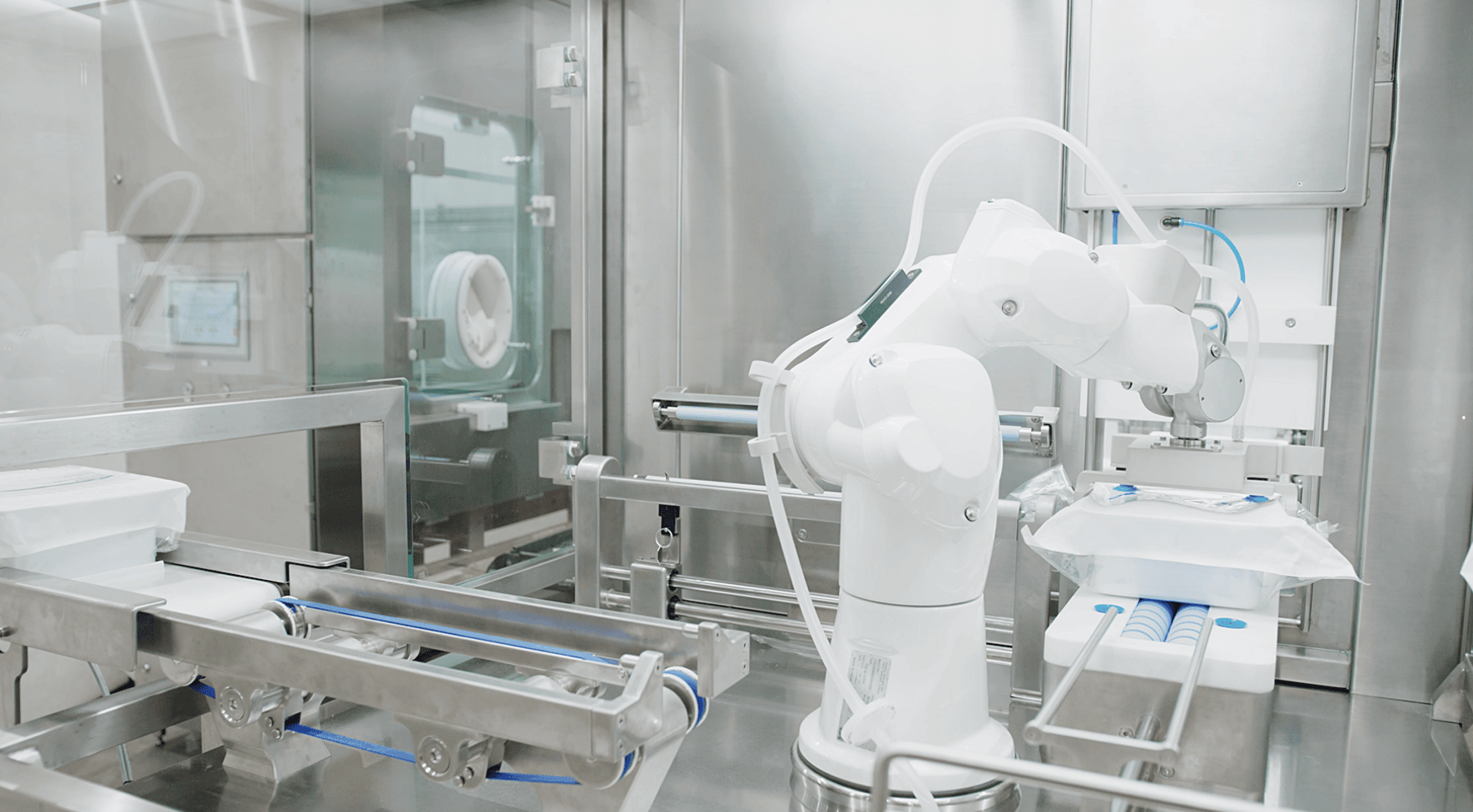

The newly unveiled AST isolator and the latest generation GENiSYS C are two of AST’s intuitive, compact solutions for high-value liquid pharmaceuticals requiring maximum yield and complete product stewardship. Designed with superior flexibility and ultimate efficiency, both these products are built to meet the multi-modal requirements of many of today’s parenteral drug manufacturers looking to keep their operational footprint small and their drug development process agile.

The GENiSYS C combines robust automation with easy-to-operate processes and recipe-driven production, utilizing features traditionally found in large-scale filling lines to process a variety of ready-to-use and custom containers.

The AST isolator is next-generation barrier technology leveraging innovative automation and a user-friendly design for a best-in-class isolator solution that integrates exclusively with AST’s aseptic processing systems.

Learn how AST can provide your organization with 100 percent integrated isolated fill-finish technology – reach out to our experts today.