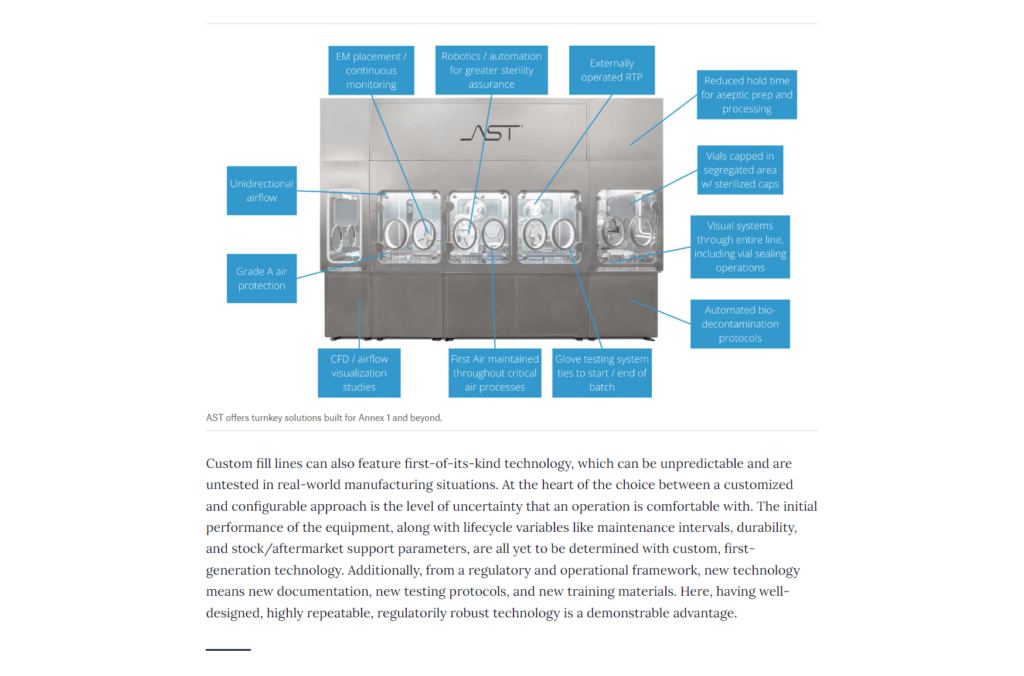

Pharma Tech Focus Magazine recently spotlighted AST’s modular approach to providing aseptic processing solutions. A central aspect of this approach is providing full service through a variety of turnkey solutions: a suite of proven, standardized tools and technologies utilized in the filling line design and configuration. And as all aseptic processing environments have design considerations for both product processing and broader facility requirements, any approach to turnkey implementation should include the entire project timeline. The project ramp-up and launch is a key area in the time-to-market equation that an operation can address and improve, highlighting the importance of finding a full-service partner with expertise that considers the planning, installation, operation, and servicing of an aseptic processing system.

With the industry moving at an accelerated speed with developmental breakthroughs in patient-centered medicine, the demand for rapid solutions, both technological and regulatory, is clear. Stakeholders are consistently looking for a path forward that prioritizes the highest standards of product safety and efficacy, all while getting products to patients in need in the shortest amount of time possible. Configurable, modular technology is part of a larger strategy that enables AST to walk side-by-side with our customers every step of the way and includes the key areas of integrated technology, process-improving solutions, and aftermarket support.

100-percent integration means time saved. A fill-finish system is comprised of complex equipment capable of precise processes. In some cases, crucial aspects of the solution, like the barrier technology, fill-finish machine, and decontamination system, may have different designs or HMIs, and significant work may be needed to harmonize the overall solution. Having a single provider that offers cross-system unified control and record-keeping saves crucial time in training and operating the system. Full integration also saves time in the validation phase, and the use of like-technology streamlines the scaling process as a drug product goes through development.

Modular Technology: solutions that pursue quality and innovation. When the full scope of an operation can be planned, executed, and supported uniformly, key parameters and process requirements can be optimized. AST has designed modular configurations to address the majority of customer requirements and sterile parenteral needs. The challenges around highly targeted products are addressed through high-yield and end-to-end product stewardship measures available across AST’s line of solutions.

Full service – full life-cycle support. With an expert Life Science partner, the full life of your aseptic processing equipment is taken into account.With pre-engineered modules, AST provides configurable fill-finish systems designed for high performance, backed by a prepared supply chain and a dedicated team of professionals ready to meet any stocking or service requirements. The goal of any aseptic operation is to keep equipment in optimal running condition, and AST’s Customer Care team is always available with various remote and in-person support options as well as any training or maintenance support needs.

Modular, configurable technology is the foundation of AST’s approach to providing comprehensive turnkey solutions. Check out the full article to explore the benefits of a modular approach to fill-finish processing: AST Company Insight – Pharma Technology Focus | Issue 150 | January 2025