PRODUCTS

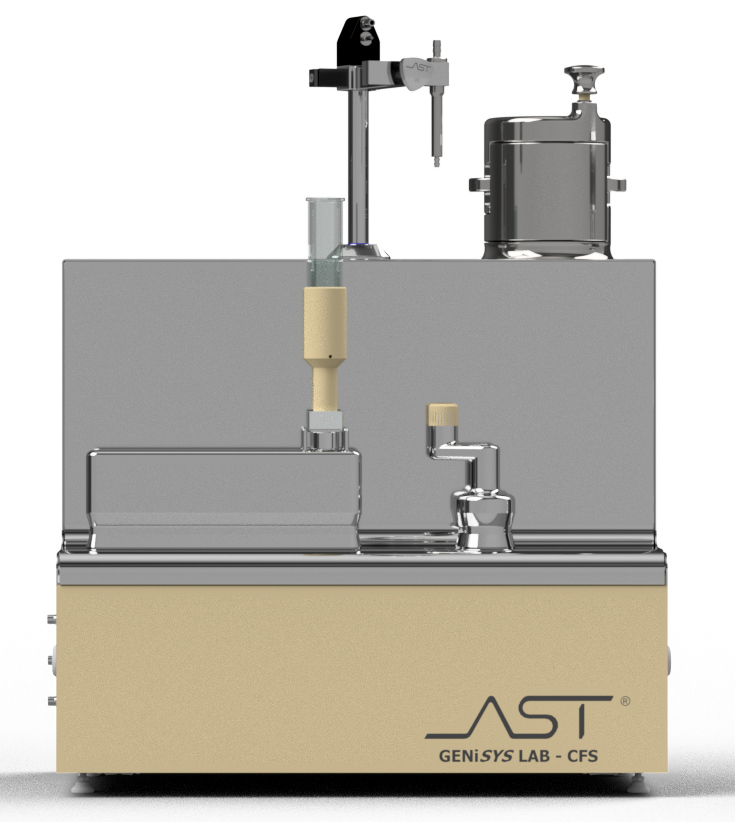

Bench-Top Vial, Syringe & Cartridge Filling System

AST’s Container Filling System (CFS) is a bench-top, semi-automatic machine used for the filling of pre-filled syringes and cartridges, and the filling and stoppering of vials and bottles. The system is designed to meet the demanding requirements for small-scale processing of sterile injectable products.

The Container Filling System was designed with cGMP in mind. Its compact, aseptic design provides complete compatibility with cleanrooms, bio-safety cabinets, laminar airflow hoods, and aseptic isolator environments.

The system’s versatility, features, and compact size make it ideally suited for labs and cGMP small batch filling.

In the Know

Advanced Automation from the First Fill

The Container Filling System is integrated with an advanced product dispensing system that provides consistent and accurate product dispensing. integrated pump technology provides accurate product and is available with AST’s peristaltic pumps for minimal product shear while using a pre-sterilized single-use fluid path. Rotary piston pump options are also available for more viscous product handling.

When integrated with an electronic weigh scale, the system can fill the container while measuring the dispensed material and providing automatic fill adjustments to the pump as required. The system’s electronically controlled axis inserts the filling needle into the container and slowly lifts it to minimize shear, foaming, or product agitation.

CFS Highlights / Benefits:

- Accurate and gentle product dispensing

- Fill vials, syringes and cartridges with a single machine

- Optional integrated weigh scale for real-time fill weight measurement

- Can be configured with peristaltic or rotary piston pumps

- Intuitive touchscreen interface for easy system operation

- Inert gas purging during filling

- Tool-less format change parts

- Optional Electronic Batch Reporting (EBR) system

- Compact system footprint allows placement within an isolator, bio-safety cabinet or laminar airflow hood