CMO/CDMO

Contract Manufacturing and Development Organizations (CMO/CDMO)

Having the right balance of capacity and capabilities in all market conditions is the struggle that Contract Manufacturer Organizations face daily. Add to it the cost and complexity of maintaining a suitable parenteral manufacturing facility, the risks can be high. With constantly evolving parenteral market needs, having flexibility while achieving high utilization is key to long term success.

To support these challenges, AST’s line of aseptic filling and closing machines provide adaptive fill-finish capabilities to ensure that any contract manufacturing organization has the right capabilities for any vial, syringe filling or cartridge application.

In the Know

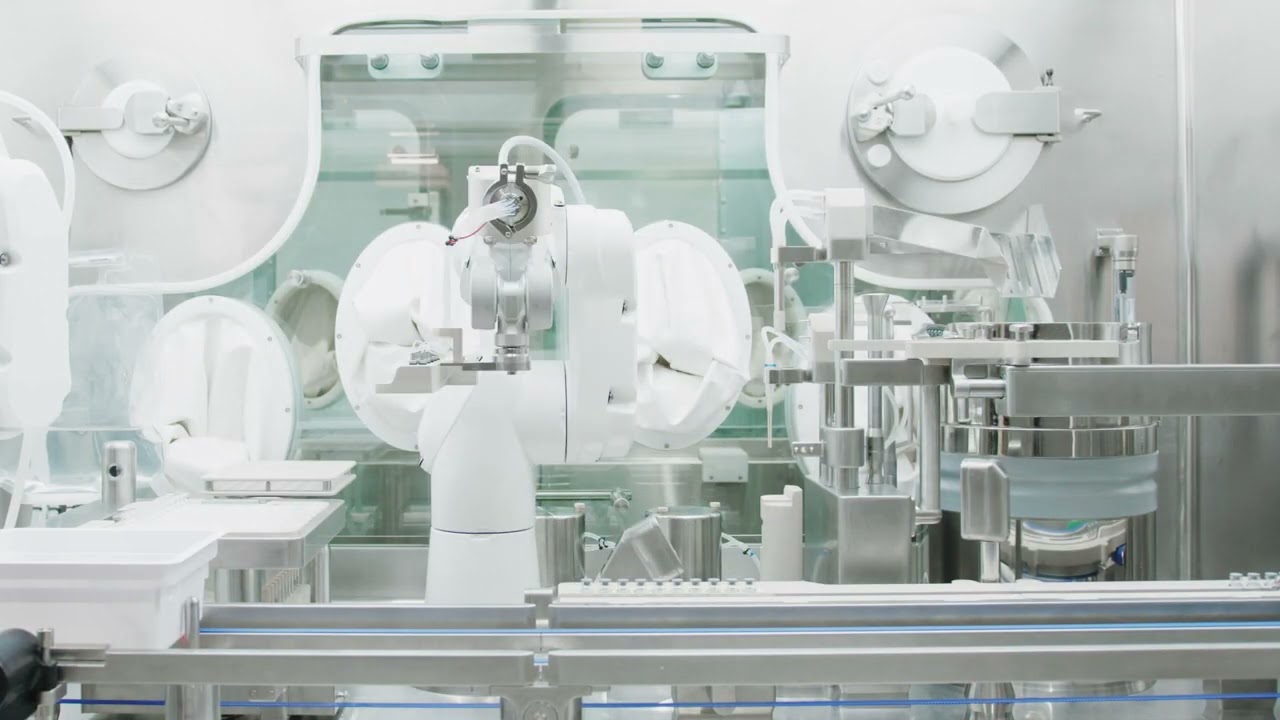

ASEPTiCell® Manufacturing Solutions

- The ASEPTiCell® A multi-format filling and closing system are ideally suited for any CMO that is focused on the pilot to commercial-scale production of sterile injectables. Its adaptive capabilities allow it to process pre-sterilized, ready-to-fill vials, syringes and cartridges.

- By processing ready-to-use containers investment in capital equipment needed for container, preparation is eliminated, cleanroom footprint is minimized and expensive utilities like Water for Injection are not necessary.

- By minimizing the complexity and cost of integrating a filling line into your operation CMOs can reap the benefits of improved return on investment when compared with other equipment alternatives.

Additional automated capabilities can be provided with the ASEPTiCell®

GENiSYS® Manufacturing Solutions

- Similar to the ASEPTiCell® ,GENiSYS® can also process ready-to-fill vials, syringes, and cartridges on a single machine. Its size and production rate make it the perfect solution for CMOs focused on early-stage clinical materials manufacturing.

- Hand filling clinical trial materials is risky. GENiSYS® eliminates this risk by automating the critical filling and closing processes for small clinical batches.

- As the product progresses through the clinical process and manufacturing is scaled, the process used by the GENiSYS® machine can be directly scaled to larger filling lines with minimal tech transfer.

On-Board AST as your Biologic Manufacturing partners

Request a consultation and a team member will contact you soon! We strive to provide an exceptional customer experience by providing innovative solutions.

Related Content

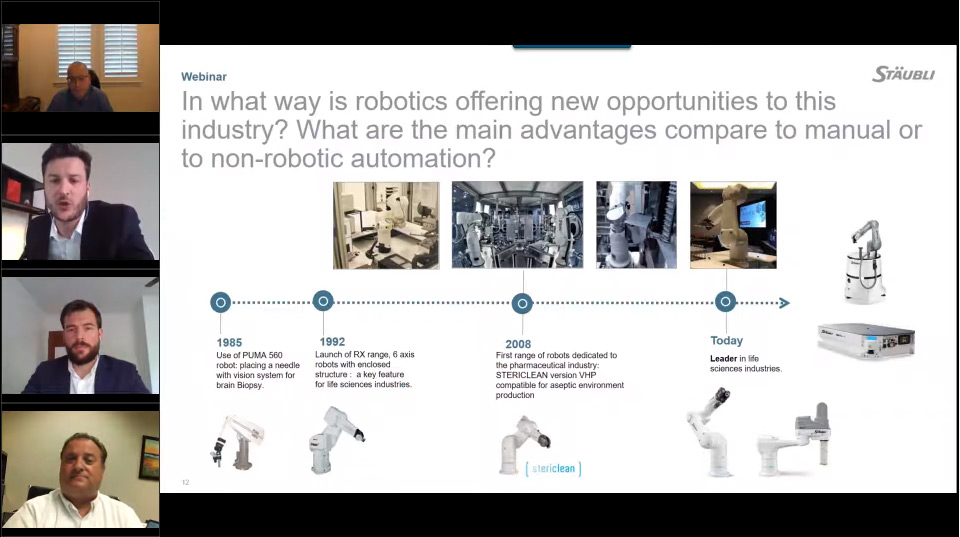

The Advantages Of Robotics In Aseptic Fill Finish

AST’s latest whitepaper on robotics, now available for download.

How Robotics Offer New Answers to Today’s Challenges

Staubli presents a panel discussion webinar on robotics with Joe Hoff

Sterile Filling Challenges for Early-Phase Product Development

Joint webinar with Pii on aseptic product development